The Only Guide to Laser Scanning Solutions, Llc.

Table of ContentsSome Of Laser Scanning Solutions, Llc.The Only Guide for Laser Scanning Solutions, Llc.The Best Guide To Laser Scanning Solutions, Llc.Laser Scanning Solutions, Llc. Can Be Fun For Everyone

In order to position a laser beam in 2 dimensions, it is feasible either to rotate one mirror along two axes - utilized mainly for sluggish scanning systems - or to reflect the laser light beam onto two carefully spaced mirrors that are mounted on orthogonal axes (https://giphy.com/channel/laserscann1ng). Each of both flat or polygon (polygonal) mirrors is then driven by a galvanometer or by an electrical motor respectively

Lots of laser scanners even more enable transforming the laser strength. In laser projectors for laser Television or laser screens, the 3 basic shades - red, blue, and eco-friendly - are incorporated in a solitary beam and after that reflected together with two mirrors.

Modern lasers can cut steel blocks with a thickness of 10 centimeters and even more or ablate a layer of the cornea that is just a couple of micrometers thick. The capability of lasers to set fluid polymers, along with laser scanners, is utilized in fast prototyping, the capability to melt polymers and metals is, with laser scanners, to generate parts by laser sintering or laser melting.

The Basic Principles Of Laser Scanning Solutions, Llc.

That card transforms the gotten vector information to motion information which is sent to the scanhead. This scanhead consists of 2 mirrors that are able to disperse the laser beam in one degree (X- and Y-coordinate). The third measurement is - if necessary - understood by a specific optic that has the ability to move the laser's centerpiece in the depth-direction (Z-axis).

For these instances it is necessary that the laser has as tiny a focal point as feasible (3d building scanning services near me). For enhanced laser scanning applications and/or high product throughput throughout production, scanning systems with greater than one scanhead are used. Right here the software application needs to control what is done precisely within such a multihead application: it is feasible that all readily available heads need to mark the exact same to end up handling much faster or that the heads mark one solitary job in parallel where every scanhead performs a component of the work in instance of large workplace

In these tools, a semiconductor laser light beam is typically checked with the aid of a powerful mirror scanner. In order to determine its relative setting to the room station, laser scanners developed into the front of the space transporter check the form of the area station and after that establish, with a computer system, the maneuvering commands.

The uses just listed which are only a small tasting of laser scanning applications have widely differing technical demands. This includes criteria like scanning speed, the size of the area or volume that need to be covered, the laser power entailed, the price, dimension, dependability, and life time of the scanner, and a lot more.

Examine This Report about Laser Scanning Solutions, Llc.

Depending upon the nature of the job, galvanometer scanners are often used in pairs. Especially, in this instance they are placed with their check directions at appropriate angles to every other. This enables the laser beam to get to any kind of factor in an airplane. For numerous applications, specialized scan optics, like an F-theta lens, are used to focus the beam on the last surface area.

Going back to 1960, when Theodore Maiman developed the very first laser, this form of light has actually evolved into a device used throughout markets. From clinical therapy to production handling, the power of lasers is made use of across a myriad of sectors and for numerous sorts of applications. When most believe of lasers, the common red light lasers typically enter your mind.

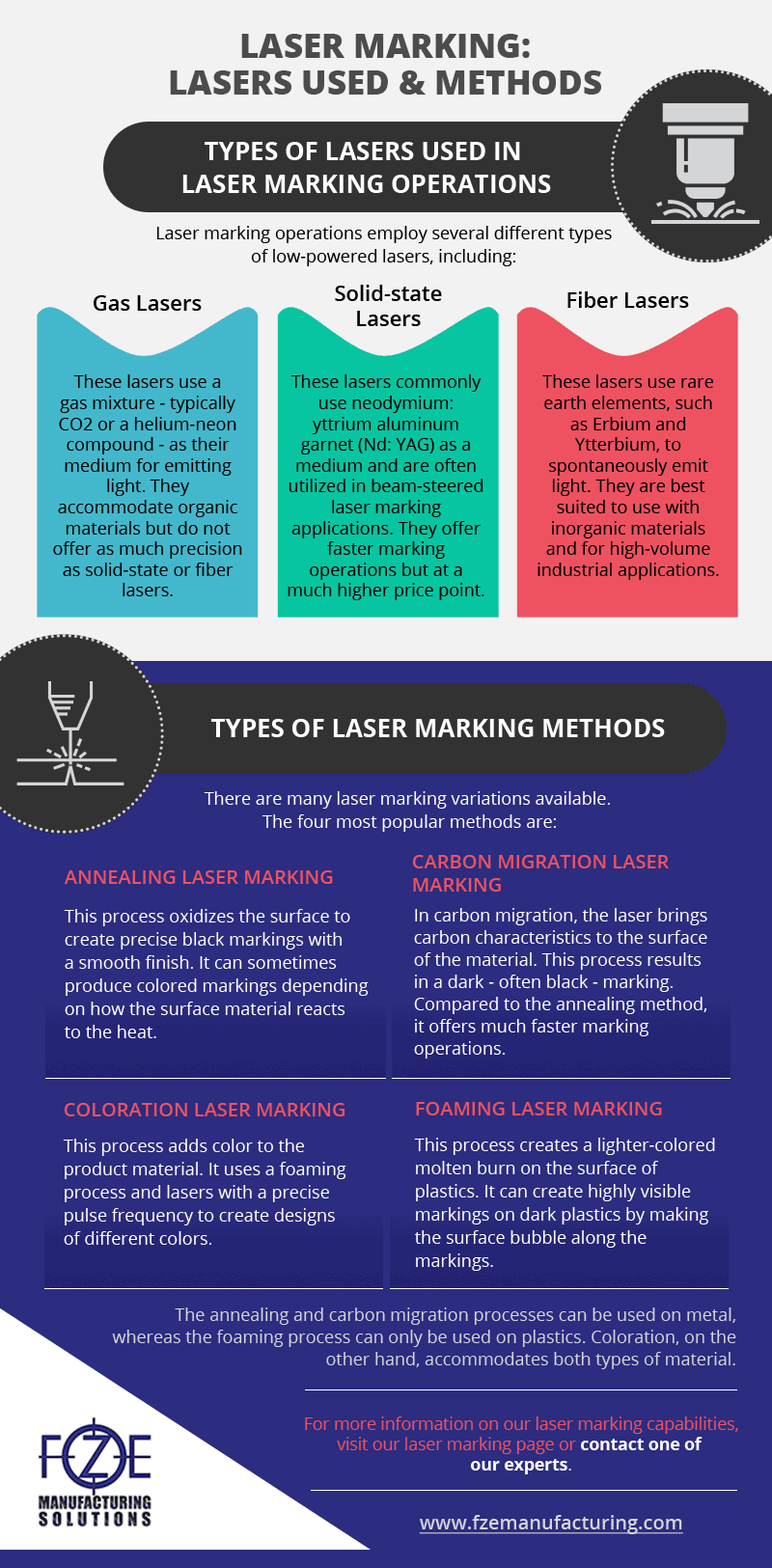

Actually, there are over 8 types of lasers throughout 3 classifications! In this blog, we'll check out each category of laser, what the group involves, utilizes for lasers, and eight various kinds of laser makers that compose these classifications - bim modeling. Light wavelength distribution map Solid-state lasers are types of lasers that make use of a strong material as its gain medium.

The 8-Minute Rule for Laser Scanning Solutions, Llc.

When a laser diode shines light on original site the doped product, the neodymium atoms are delighted and give off light. This light is after that magnified by the product and released as a laser beam. YVO4 needs huge amounts of power to produce a stable high-output power amount. This tool has recently taken over in appeal contrasted to YAG tools.

These laser kinds make use of gas as the medium instead of a strong or liquid. The 4 kinds of gas lasers are CO2, He-Ne, excimer, and argon. CO2 gas lasers have the lengthiest wavelength compared to fiber, YAG, and YVO4.

Due to the fact that of the lengthy wavelength, there is more warmth transfer than various other lasers. Carbon dioxide lasers are frequently utilized for cutting products.